Hydraulic Repairs

Dismantle & Assessment

• On arrival all components are documented, cleaned and completely dismantled

• All wearing parts are precisely measured and the result recorded

• Hydraulic components that have excessive or unusual wear are subject to further review

• The results of the inspection procedures are then used to develop an effective scope of work

Quoting & Procurement

• Internally developed, Quality Assured disassembly and inspection sheets are utilised to provide efficient and accurate information transfer between the technical and administrative staff

• An extensive inventory is maintained, ensuring fast turnaround and reducing reliance on secondary suppliers

• HYCON has access to genuine parts for the world’s leading brands through a diverse international supply chain

Grinding

• All surface grinding is completed in-house to maintain quality standards

• A larger diameter wheel is used to ensure superior finish

• This grinder is supported by a large range of jigs and fixtures to facilitate rapid turnaround

Lapping

• HYCON has extensive internal lapping capabilities with five lapping machines

• Where external Lapping Services are required, HYCON engages a specialised provider

• The lapping room tables are audited daily to maintain accuracy

• Both flat and spherical components are catered for

• Optical flats, in conjunction with monochromatic light, are used to check flatness lapping

• All lapped components are ultrasonically cleaned to remove any residue

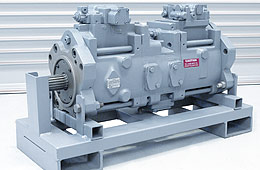

Assembly

• All components are reassembled by skilled technicians with years of experience using Quality Assured processes

• All critical dimensions are counter checked, with measuring equipment that is calibrated monthly

• All critical specifications, assembly dimensions and tensioning requirements are recorded for quality assurance and future reference

• Overhead cranes with creep mode hoists enable the precision assembly of large and heavy components

Testing

• All hydraulic components are subject to an exhaustive and authentic function test using a facility unrivalled in Australia

• Four test stands are available (110,250,300 and 1000 kW), and these can be run simultaneously

• The largest pumps can be tested at full displacement and design pressures, at the correct speeds

• All tests are logged and analysed using Hydrotechnik 5070, 8050MC hardware and software with VSE flowmeters

• Special care is taken to protect components when testing, oil flow is full flow filtered to 10 micron and off line filtered to 3 micron

Sealing & Packing

• Ports on repaired components are sealed with steel blanks at the completion of testing, preventing ingress of contaminants and loss of oil during transportation and storage

• Unpainted machine faces are coated to prevent corrosion

• All components can be packaged and transported per customer requirements. Hycon can offer the following Options:-

- Metal Transport Box

- Wooden Crates

- Anti Corrosion film covering on skid